The primary purpose of sweeping a chimney or flue for a wood burning system is to remove dangerous formations of creosote. Creosote is a combustible substance that is generated by incomplete combustion of wood. In general, it will be produced in relative proportion to the amount of wood that is burned. Creosote formation is significantly impacted by the moisture content of the wood and the amount of oxygen that is introduced into the combustion chamber. Slow, cool fires will generally produce more creosote.

Creosote forms in three stages. The first stage is powdery and loose. The second tends to be more flakey and dense. The third type is a very hard glazed substance that is very difficult to remove. It usually requires a rotary scrubbing and sometimes must be treated chemically.

The time required to properly sweep a wood burning system is about 1 to 1 & ½ hours. Factory built fireplaces are generally the quickest and wood stoves take a little longer.

The process of sweeping should include a very basic inspection known as NFPA Level 1. The inspector is looking for flue obstructions, combustible deposits, and appliance installation and connection. Only readily accessible areas of the system are examined. Some people request a more detailed inspection known as an NFPA Level 2 and Level 3. These are not normally performed unless dictated by particular circumstances or at the customer’s discretion. For example, a Level 2 is the standard inspection for real estate transactions.

Wood burning systems should, at a minimum, be inspected annually and swept as necessary. Some systems will require more than one sweeping during the heating season when they are subject to heavy usage.

There are three basic categories of wood burning systems. Open faced fireplaces are the most common in this area. Free standing stoves and fireplace inserts the other two. There are variations within each category and this page will explain what some of these are and how they should be properly serviced.

Open Faced Fireplace

Open Faced Fireplaces: Although fireplaces are not considered very efficient, they remain popular, especially for people who only have occasional fires. They are susceptible to all three types of creosote formation. They are especially susceptible to third degree creosote when they are located on an outside wall.

The main components of a fireplace are the firebox, damper, smoke chamber, smoke shelf, and flue. The firebox is the visible enclosure where the wood is burned. The damper is the opening at the top of the firebox that allows the smoke to be vented when it is opened. The smoke shelf is a flat area just behind the damper. The smoke chamber is the area between the damper and the flue. The flue is the vertical passageway that goes from the smoke chamber to the top of the chimney. Clay tile is the most common flue liner followed by stainless steel. Some older homes in this area do not have any liners, just brick and mortar. These unlined flues have a much greater potential for malfunction.

Unfortunately, there are some chimney sweeps who neglect to sweep the smoke shelf and smoke chamber. They do this because it is somewhat difficult and can take an extra 20-30 minutes if done properly. The only way to access this area for cleaning is from below, through the firebox. If this area is not cleaned then it has a very high potential for ignition because of its proximity to the fire in the firebox.

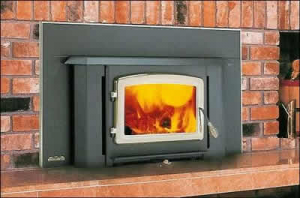

Fireplace Insert

Fireplace Inserts: A fireplace insert is a wood burning appliance that is manufactured to fit inside the firebox of an existing open faced fireplace. They are significantly more efficient and produce a great deal more heat. The two main components to be swept are the firebox or combustion chamber and the flue liner. Newer inserts often have a horizontal baffle at the top of the combustion chamber that produces a secondary burn of the combustion gases. The baffle must be removed for cleaning although they can sometimes be vacuumed off.

There are some older fireplace inserts still in service that are not directly connected to a flue liner. The combustion byproducts vent directly into the original fireplace firebox and smoke chamber before they rise up to the original fireplace flue. These installations are extremely prone to excessive creosote formation and are consequently more dangerous to use. In most cases, these types of inserts must be completely removed from the firebox before sweeping. Otherwise, it is nearly impossible to access the smoke shelf and smoke chamber.

It is recommended that these older inserts be brought up to current standards by installing a stainless steel flue liner that connects directly to the appliance. An even better solution would be to upgrade the insert to a newer more efficient model.

Wood Burning Stove

Wood Burning Stoves: These are free standing units that are typically constructed of cast iron or steel. They often connect to a chimney system by means of a steel connector pipe. Both the connector pipe and the chimney flue must be swept in order to remove creosote deposits. There is often a baffle in the firebox that must be serviced as well.

Wood stoves in particular must be installed with proper clearances to combustible material. A permit and certificate of compliance should be on file with the local municipality for these units. This will offer some assurance that the stove was installed properly. Remember, this does not guarantee that the installation was not altered after the permit was issued. The chimney professional should be checking for these clearances and possible modifications as part of the Level 1 inspection process.